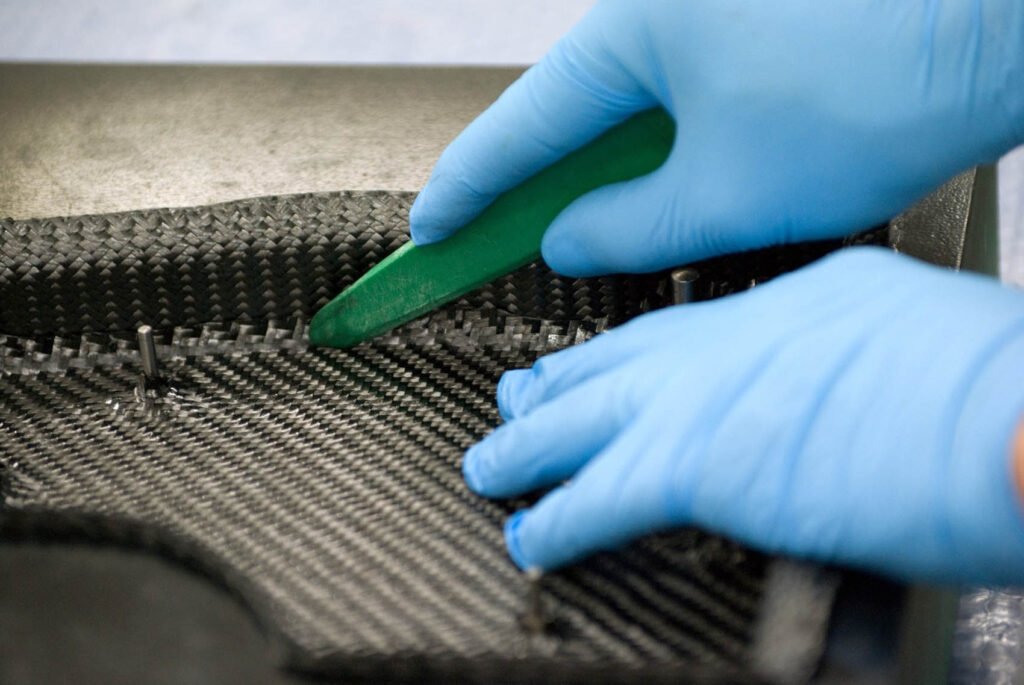

After the success of the first edition of the Shell Marathon, we decided to contribute to the development of the new inner shell of the electrically powered vehicle. It would no longer be created through the traditional process of manually laying carbon fibres down and subsequently drying them, but rather from a milled CNC model/mould in aluminium, with autoclave process.